Articles | Talking Trade

Gypsum and plaster at Winstone Wallboards

Tuesday, 23 April 2024

By Dharita Rajani

Gypsum plays a crucial role in materials like plasterboard, plaster, and compounds. The dynamics between gypsum and plaster help us understand the multifaceted nature of this mineral; its role in construction; and the benefits of gypsum in today’s architecture.

Gypsum is a naturally occurring mineral characterized by its composition of calcium sulphate. It is processed at Winstone Wallboards to make plaster which is then used to make plasterboard, setting and powder compounds. Plaster is a derivative of gypsum which is obtained by removing its water content.

Free water versus crystalline water

When we look more closely into the components of this water content, free water is water that can be easily removed from simple drying. Removing free water usually occurs without changing the structure or composition of gypsum.

Combined water or crystalline water, on the other hand, is water that cannot be easily removed. Typically, we cannot get this type of water out without changing the structure or composition of gypsum.

When making plaster, we convert the dihydrate (CaSO4.2H2O) to hemihydrate (CaSO4.½H2O). This process of converting gypsum to plaster requires the application of heat to remove the crystalline water.

The structure of gypsum and plaster

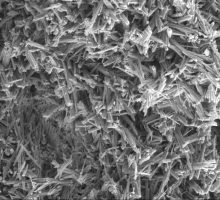

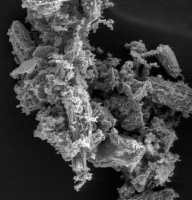

In gypsum, we see a beautiful crystalline structure which is interlaced and needle-like, whereas in plaster, the crystalline structure seems to be broken and is in a fuzzier state (Fig 1. & 2.).

Fig 1. Gypsum at 50 micrometre SEM Fig 2. Plaster at 50 Micrometre SEM

When we process plaster, we also use hammer milling and air separation to achieve the correct particle size of plaster to make the wallboard slurry, compounds or to be merchandised as variations of plaster itself, such as dental plaster, casting plaster or plaster of Paris.

The history of plaster

Plaster has been used for centuries in the construction industry, for decorative elements like coves, cornices, and mouldings, and the art industry due to its workability and the ability to pour the plaster slurry into a mould which will then harden into a solid form.

Wallboard, also known as drywall, plasterboard, or gypsum board, revolutionised interior construction due to its ease of installation, versatility, and cost-effectiveness. It continues to serve as an essential component in walls, ceilings, and partitions, providing structural support, fire protection, and soundproofing in all types of buildings.

Making plasterboard

When making plasterboard gypsum, which has been dehydrated to plaster, is made into a slurry with water and other additives. The manufacturing process of plasterboard entails sandwiching a core layer of this plaster slurry between sheets of craft paper, followed by exposure to temperature-regulated drying chambers to remove any remaining free water.

This heat encourages the rehydration and drying of the plaster, catalysing its hardening, and producing a robust, solid plasterboard.

The mix of plaster with appropriate additives is used to enhance the properties of plasterboard, resulting in speciality boards such as GIB Braceline® and GIB Noiseline®, which have bracing and acoustic attributes, GIB Fyreline® with enhanced fire resistance properties, and GIB Aqualine® which has water additional resistance qualities.

When plaster is combined with other dry powder raw materials, we can manufacture a variety of compounds, ranging from easy-sand through to compounds which are harder and less easy to sand, all with different setting time ranges to allow for less or more working time. These pre-prepared compounds are mixed with water on site and are applied to the plasterboard (joins, edges, screw holes etc.), which then set and harden, chemically binding to the plasterboard.

This bond occurs because the plaster compound is largely gypsum in its dehydrated state, and reintroducing water instigates the rehydration process, effectively restoring it to its original crystalline gypsum state.

Plaster + Water = Gypsum

During this re-hydration process, there is a re-forming of the crystalline structure. Because of this, setting compounds are usually recommended to be used as base coats in our GIB® systems, to enable the crystalline structure to interlock with the board paper fibres.

The recyclable and sustainable nature of gypsum

The process of removing the bound crystalline water to make plaster can occur in a repeatable loop, meaning clean gypsum waste can be recycled into new plasterboard products. Winstone Wallboards has designed this capability into the new plant in Tauranga and is looking to commission this functionality over the next 12 to 18 months. This will eventually provide an outlet for clean construction plasterboard waste, enabling industry to work in a more circular way.

Gypsum can be used in conventional, organic, and regenerative agriculture systems. It also has benefits to soil quality and performance. Used as a soil conditioner, gypsum improves texture, drainage, and aeration for clay soils. This encourages healthy root development. Gypsum assists with the recovery of sub soils exposed by earth movements due to contouring or slippage.

Applications of gypsum improve soils affected by salinity from fertiliser salts, dairy effluent, aluminium, or sodium build up.

For a biologically active soils focus, gypsum increases the activity of soil micro-organisms and earth worms, which aids in soil aeration, macropore formation and mixing of organic matter.

As a fertiliser gypsum supplies calcium and sulphate sulphur, important nutrients for plant growth and can assist the performance of other surface applied fertilisers. Gypsum can be used in animal nutrition blends around calving time.

Winstone Wallboards is currently working to expand the availability of offcut recycling throughout New Zealand and works closely with local waste companies like Green Gorilla, who have introduced a plasterboard recycling service in Auckland. Whatever board cannot be recycled can be composted. For more information on our waste collection across NZ please click here.

Winstone Wallboards is dedicated to producing materials with highest standards of quality, durability, and performance alongside our rigorous quality control measures. As we continue to innovate and advance in the field of construction materials, gypsum remains a vital part of enabling us to build safer, sustainable, and more resilient communities for the future.

Read next

Articles | Technical

Bracing elements with varying wall heights

Monday, 26 February 2024 By Richard Fuller