Articles | Technical

Skillion Ceilings - How to Ensure Best Quality of Finish

Tuesday, 10 June 2025

By Richard Fuller

Some would have seen skillion ceilings such as below. What steps can be taken at the design stage to avoid this happening?

Using metal ceiling battens will provide a relatively stable substrate for fixing plasterboard to. Metal battens will not bend, twist or warp after installation. The expansion/contraction coefficients are similar for metal and plasterboard whereas with timber the thermal coefficient is significantly less and the hygrometric coefficient significantly greater which can cause stresses between the dissimilar materials. Simply put, this means you will get more chance of movement with timber battens.

Install 13mm GIB® plasterboard on battens @600mm centres. Being thicker and stronger, 13mm GIB® plasterboard gives you extra rigidity which helps combat the effects of gravity and minimises the flow-on effect of structural movement. Fasten sheets at right angles to battens and in accordance with the GIB® Site Guide or relevant GIB® Systems literature.

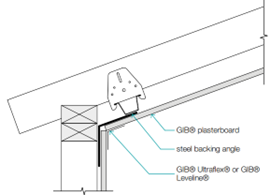

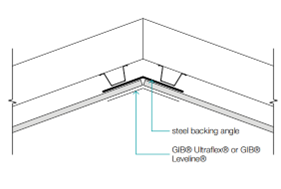

Folded metal angle minimum 0.55mm BMT with 100mm each leg at junctions. This ties ceiling planes and ceiling to wall lining together creating a strong joint with less chance of movement/cracking.

Avoid penetrating the GIB® plasterboard ceiling with recessed lighting, speakers and the like. Preventing this airflow helps stop the warm moist air from the habitable space below entering the structure which can cause structural movement and/or condense causing durability issues.

To limit sag in GIB® plasterboard ceilings, long term uniformly distributed loads (e.g. fixtures and fittings and/or overlaid insulation) should not exceed 4.2kg/m2 for insulation or 1kg/m2 for fixture weight unless independently supported.

All artificial lighting should use soft diffuse bulbs and where possible include shades to direct light downwards reducing the amount of glancing or critical light.

Consider specifying a Level 5 finish. All butt joints should finish off framing and be back blocked, this will enable the formation of a tapered edge. All sheet edge joints also to be back blocked. Back blocking strengthens and stabilises the joints between GIB® plasterboard joints. This becomes a requirement when there are 6 or more tapered edge joints in a ceiling area with metal battens and 3 or more tapered edge joints with timber battens.

Where high level windows are a design choice, consider sheet orientation so longitudinal sheet joints run away from the light source. External window shades will also reduce the direct critical light effect.

Ceiling linings are to resist the flow of air to avoid transporting airborne water vapour into the skillion roof cavity from the space below. In some scenarios a vapour barrier layer is installed to help resist this flow. When installed this should be in accordance with manufacturers installation instructions and be directly below roof framing prior to installing the ceiling battens.

There is a wider industry understanding of the importance of ventilation of the skillion ceiling space. This should be created in line with the purlins. Use either ventilated or counter battens to create the ventilation plane. Ventilation should run from the eave level up to ridge line so drying air can rise up the roof plane.

Lastly, any questions call the GIB® Helpline 0800 100 442

Read next

Articles | Technical

More Than Just Plasterboard: The Expert Support That Saves You Time and Money

Tuesday, 10 June 2025 By Russell Pedersen